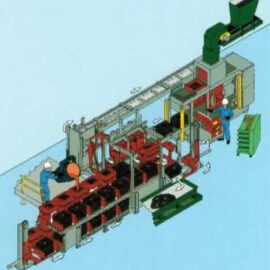

Linear Mold Handling Systems

Hunter’s Linear Mold Handling Systems provide an efficient and compact solution for managing flaskless mold storage, pouring, and cooling. Designed for high-quality and cost-effective mold handling, these systems ensure smooth operation with minimal manpower and low operating costs. Features include automated mold storage on bottom boards, precise weight and jacket placement, and a flexible design suitable for aluminum, brass, gray, or ductile iron casting. With expandable modules and controlled cooling cycles, Hunter’s Linear Mold Handling Systems improve productivity, optimize casting quality, and maintain a clean working environment.

| Product Type | Mold Handling System |

|---|---|

| Model | HLH TYPE I System |

| System Type | Single Row Pouring Line |

| Operation Type | Automatic Mold Conveying and Pouring Line |

| Cooling Time | Up to 30 minutes |

| Pouring Method | Single Station Pouring or Multi-Position Pouring |

| Product Type | Mold Handling System |

|---|---|

| Model | HLH TYPE II System |

| System Type | Double Row Combined Pouring and Cooling Line |

| Operation Type | Dual-Pass Pouring and Cooling |

| Cooling Time | Up to 45 minutes |

| Product Type | Mold Handling System |

|---|---|

| Model | HLH TYPE III System |

| System Type | Triple Row Combined Pouring and Cooling Line |

| Operation Type | Triple-Pass Pouring and Cooling |

| Cooling Time | Up to 1 hour |