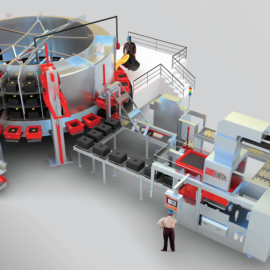

Turntable Mold Handling Systems

Hunter’s Turntable Mold Handling Systems are engineered for efficient flaskless green sand mold handling, optimizing mold pouring, cooling, and discharge processes. Molds are automatically transferred from the molding machine onto a turntable system, where they undergo precise weight and jacket placement before reaching the pouring zone.

The multi-level cooling system allows operators to select 2, 3, or 4 cooling levels, ensuring controlled in-mold cooling based on casting requirements. As molds complete their cooling cycle, they are discharged via an automated chute to a shake-out conveyor. This system enhances productivity, consistency, and space efficiency in foundry operations.