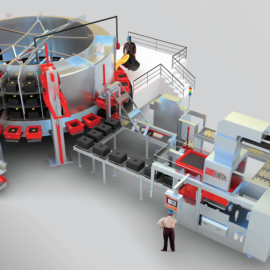

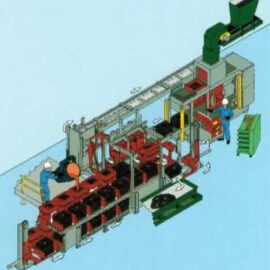

Designed for the efficient handling of flaskless green sand molds.

Cooling times up to 30 minutes

- Weights and jackets are automatically set

- Molds are poured and the cooling cycle begins

- Table continues to index, completing one revolution

- Weights and jackets are stripped

- Molds are elevated and pushed onto level 2

- Cooling continues for one more rotation of the table

- Molds are discharged to a shake-out or cooling belt

Key Features:

- Efficient Handling of Green Sand Molds: Designed specifically for flaskless green sand molds, providing efficient handling and cooling capabilities for high-performance foundries.

- Cooling Time: Molds are cooled for up to 30 minutes, ensuring optimal cooling for each mold while reducing production times.

- Automatic Weight and Jacket Setting: Weights and jackets are automatically set on the molds, ensuring precise cooling control for consistent results.

- Automated Pouring and Cooling Cycle: After pouring, the cooling cycle begins immediately, and molds are indexed automatically to the next stage, ensuring smooth operation.

- Rotating Table System: Molds are placed on a rotating table that continues to index, completing one full revolution for each cooling cycle.

- Weight and Jacket Stripping: After cooling, the weights and jackets are automatically stripped off, allowing for easy and efficient mold processing.

- Elevating and Pushing Molds to Level 2: Once the molds complete their first cooling cycle, they are elevated and pushed onto Level 2 for additional cooling.

- Continued Cooling: The molds continue cooling for one more rotation on the second level, ensuring consistent cooling during the entire cycle.

- Final Discharge: After the cooling process is complete, the molds are discharged either to a shake-out system or a cooling belt for further processing.

Benefits:

- Efficient Cooling: The dual-level system provides efficient cooling for flaskless green sand molds, improving cycle times and mold quality.

- Automatic Mold Handling: Weights, jackets, and mold indexing are all automated, which enhances operational efficiency and reduces manual labor.

- Space-Saving Design: The dual-level system maximizes space by utilizing two levels for mold cooling, making it ideal for facilities with limited floor space.

- Quick Cooling Cycle: Cooling times of up to 30 minutes are optimized for fast production, allowing for more molds to be processed within a given time.

- Reliable Shake-Out System: The cooled molds are easily discharged into either a shake-out system or a cooling belt, ensuring smooth and efficient mold handling.

- Scalability: The system can handle a wide variety of mold sizes and volumes, making it adaptable to the needs of different foundries.

Applications:

- Green sand casting operations

- Efficient cooling and handling of molds in flaskless mold systems

- Foundries requiring quick and effective mold cooling

- High-performance casting systems that need automated mold cooling

Details

| Product Type | Dual-Level Cooling System for Flaskless Green Sand Molds |

|---|---|

| Model | HV-Dual Level |

| System Type | Dual-Level Cooling and Mold Handling System |

Reviews

There are no reviews yet.