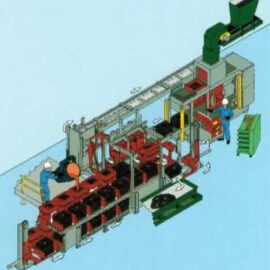

Single Row Pouring Line

Cooling times up to 30 minutes

Sequence of Operations

The mold is pushed out of the molding machine onto a self storing automatic mold conveyor. This conveyor provides unpoured mold storage and quickly transports molds on demand to the pouring line.

The mold is then pushed off the aluminum bottom board onto a graphite lined cast iron pouring pallet. Bottom board is returned automatically to the molding machine.

After the mold is pushed onto the pouring line, the weight and jacket are automatically set. The weight is set first and then the jacket, insuring that setting the jacket does not cause mold shift.

Molds are gently indexed forward to the pouring zone. Molds can be automatically indexed to the pourer for single station pouring or the pourer can move up the line to pour at multiple positions.

After pouring, the molds continue to cool under weights and jackets until they reach the end of the pouring line. At the end of the line a combination lowering and transfer device lowers the pallet and mold (with the weight and jacket in place) from the top to the bottom level. It then pushes the line of pallets on the bottom level forward one position in the opposite direction.

The molds continue to cool on the bottom level as they move toward the lift transfer device on the other end of the system. This unit lifts the pallet from the bottom to the top level, and then pushes the line of pallets on the top level forward one position in the opposite direction.

The weight and jacket are then stripped and the cooled mold is pushed laterally onto a vibrating pan or shake-out conveyor (provided by others). The weight and jacket are then set down on the empty pouring pallet and indexed forward one position to the mold loading station. The weight and jacket are then picked up and the sequence repeats as a new unpoured mold is pushed onto the pallet and the weight and jacket are precisely set on the incoming mold.

Key Components:

- Self-Storing Automatic Mold Conveyor

- Graphite Lined Cast Iron Pouring Pallet

- Weight and Jacket Adjustment Mechanism

- Combination Lowering and Transfer Device

- Vibrating Pan or Shake-out Conveyor (Provided by Others)

Key Features:

- Automatic Mold Handling: The mold is pushed out of the molding machine and onto an automatic conveyor that transports molds on demand to the pouring line.

- Unpoured Mold Storage: The conveyor provides quick and efficient storage of unmolded products.

- Seamless Mold Transfer: After the mold is pushed onto the pouring line, weight and jacket settings are automatically adjusted to ensure smooth operation and no mold shifting.

- Flexible Pouring Process: Molds are gently indexed forward to the pouring zone and can be poured either by a single station pourer or multiple positions along the line.

- Cooling Process: Molds continue to cool under weights and jackets until reaching the end of the pouring line.

- Mold Transfer System: A combination lowering and transfer device is used to lower and transfer pallets from the top to the bottom level of the pouring line, ensuring proper cooling.

- Weight and Jacket Handling: At the end of the line, the weight and jacket are stripped off, and the cooled mold is moved laterally to the shake-out conveyor for further processing.

Benefits:

- Optimized Efficiency: Automates the entire pouring and cooling process, significantly improving foundry efficiency and reducing labor requirements.

- Consistent Pouring: Automated weight and jacket setting prevents mold shifting, ensuring consistent pouring quality.

- Space-Saving Design: The self-storing conveyor and mold handling system allow for efficient space utilization in the foundry.

- Flexibility in Pouring: Allows for single or multi-position pouring, adaptable to various production needs.

- Enhanced Cooling: Molds are continuously cooled under weights and jackets for better quality and reduced production time.

Notable Features:

- Automated Cooling and Pouring: The system ensures consistent cooling of molds with adjustable weight and jacket placement.

- Vibrating Pan/Shake-Out Conveyor: Efficient mold unloading and final processing of cooled molds.

- Energy-Efficient Design: The entire mold handling system is designed for efficient energy use, reducing operational costs.

- High Productivity Potential: The continuous mold movement through the system increases the throughput and reduces downtime.

Details

| Product Type | Mold Handling System |

|---|---|

| Model | HLH TYPE I System |

| System Type | Single Row Pouring Line |

| Operation Type | Automatic Mold Conveying and Pouring Line |

| Cooling Time | Up to 30 minutes |

| Pouring Method | Single Station Pouring or Multi-Position Pouring |

Reviews

There are no reviews yet.